i.c.r

cleanroom

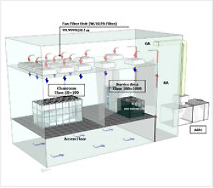

Industrial Clean Room

Based on the experience of carrying out a number of FAB-construction with turnkey, the expected problems are presented in advance, and countermeasures are proposed to construct the interior, air conditioning, system sealing, automatic control, electricity, and utility of the cleanroom. Also, we are accumulating technologies that can be constructed with Turn-Key, from building planning to design, purchase, construction, quality control, commissioning and TAB.

Consulting

Based on years of experience in performing construction and technical know-how, we identify and review expected problems in the initial planning stage of the project and present the best plan.

1. Receive Customer

2. Business Feasibility Review

3. Laws and Regulations Review

4. Production Process Review

5. Cost Review

6. Submission of Optimal Solution

Design

From conceptual design to detailed design, the group of professional design personnel prepares investment savings with differentiated designs based on the characteristics of each product.

1. Cleanroom Conditions Review

2. System Selection

3. Heat Load Calculation

4. CleanLiness Review

5. Device Review

Construction

We take the lead in improving the production yield of customers with our constant research on construction technology, optimal construction management process, and know-how of turn-key construction experience accumulated over many years.

1. Schedule Management

2. Cost Control

3. Process Management

4. Safety Management

5. Quality Control

6. Material Selection Management

7. Cleanroom Construction

8. Test Run and Final Inspection

TAB

After completion of the construction, the overall system review and measurement of the clean room ensure that the design intention is satisfied and adjusted to meet the conditions suggested by the contractor.

1. Room Cleanliness Test

2. Filter Leak Test

3. Differential Pressure Test

4. Filter Surface wind Speed Test

5. Temperature & Humidity Test

6. Noise Test

7. Illumination Test

8. Equipment Performance Test

Super Clean Room

Based on the experience of carrying out a number of FAB-construction with turnkey, the expected problems are presented in advance, and countermeasures are proposed to construct the interior, air conditioning, system sealing, automatic control, electricity, and utility of the cleanroom. Also, We are accumulating technologies that can be constructed with Turn-Key, from building planning to design, purchase, construction, quality control, commissioning and TAB.

Super Clean Rooms generally have air circulation and temperature and humidity control methods in the form of vertical laminar flow, and provide the longest system for each site.

Utility

The main LINE of UTILITY piping, which is connected to the production equipment inside the clean room, includes purified water, cooling water, steam, CDA, N2, PCW, wastewater and liquor, CV, PV piping, etc.

TAB

After the completion, a follow-up inspection is conducted to see if the design functions as intended.

Testing

Quantitative performance of each equipment

- Design data review

- Design load calculation

- System diagram check

- Secure ACTUAL DATA

- Measure Air Volume, Wind Speed, and Differential Pressure

Adjusting

Adjust the air volume and quantity of each equipment appropriately

- Establish a stable system

- Check construction status

- Check construction volume and omission

Balancing

Distribution system for proportional flow rate

- Energy saving

- Energy saving through distribution of used heat sources

- Pleasant environment

- Inducing workers to improve work efficiency.